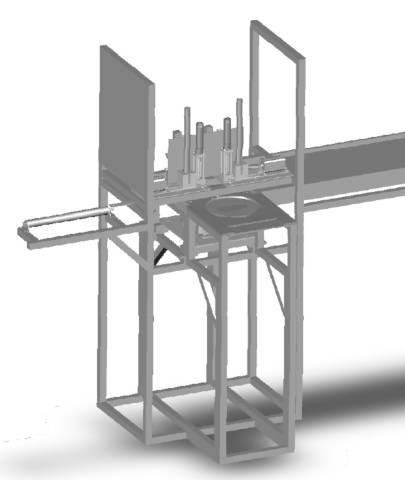

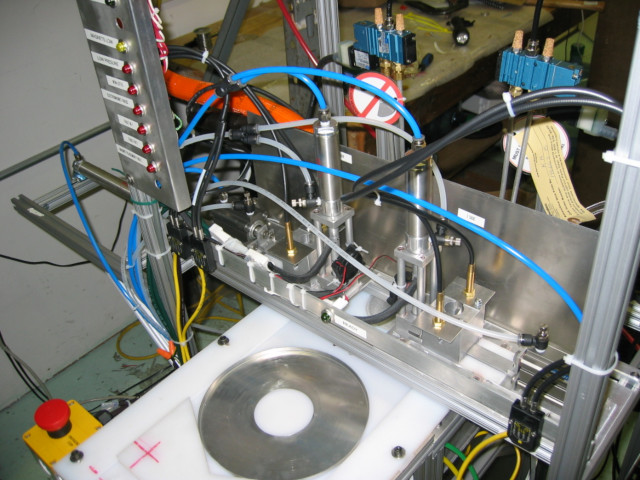

This is a custom assembly machine that was used in-house to accelerate the assembly of high-strength magnets onto a custom trim ring for recessed lighting. Tens of thousands of trim rings were produced very quickly. This kind of automation allowed a small manufacturer to do in-house high-volume work. The machines apply dots of adhesive and then place the magnets on those dots. The machines used PLC controls to manage pneumatic actuators, IR sensors, and hot melt adhesive machines.